Ground Granulated Blast Furnace Slag (GGBFS)

Brief Description

GGBFS is formed when granulated blast furnace slag (GBFS) is further processed or ground using conventional cement clinker grinding technology.

Physical Description

On a casual examination, GGBFS can be off-white in appearance and could pass for a powder fineness typically between 380m2/kg - 420m2/kg.

Method of Manufacture

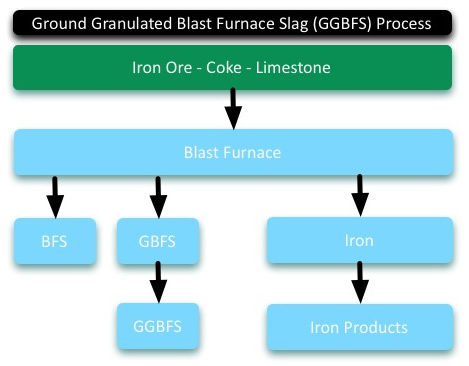

After molten slag has been quenched rapidly by passing it through a trough of high pressure, high volume water sprays, the heat energy contained in the molten slag causes it to explode and instantly form granulated blast furnace slag (GBFS).

GBFS is then further processed or ground using conventional cement clinker grinding technology to form GGBFS.

Diagram of manufacture

Applications

GGBFS is typically used in activation of granular pavement materials and as a cementitious material in the manufacture of concrete, particularly where resistance to aggressive ground, water and aggressive environmental conditions are present.

Typical uses for GGBFS are:

- Activator for stabilising granular pavement materials as the only stabilising agent or in conjunction with small quantities of lime.

- As a general cementitious replacement 25 – 50% for Portland Cement in concrete construction.

- As a significant cementitious replacement min 65% for Portland Cement where long term durability in aggressive ground, water or air environments are required.

- As a high cementitious replacement > 80% in special grout mixes.